BREAKER Parameter Item Model Weight Overall length Hydraulic working pressure Hydraulic oil flow Setting Pressure Impact Rate striking energy Hose diameter Chisel rod diameter Suitable Excavator Units (kg) (mm) bar (L/min) bar (b.p.m) (j) (inch) (mm) (ton) LC-40 LC10 79 936 90~120 15~30 130 600~1100 204 1/2 40 0.5~1.2 LC-45 LC20 105 1071 90~120 […]

Email: equip@lichmach.com

BREAKER Parameter

| Item | Model | Weight | Overall length | Hydraulic working pressure | Hydraulic oil flow | Setting Pressure | Impact Rate | striking energy | Hose diameter | Chisel rod diameter | Suitable Excavator |

| Units | (kg) | (mm) | bar | (L/min) | bar | (b.p.m) | (j) | (inch) | (mm) | (ton) | |

| LC-40 | LC10 | 79 | 936 | 90~120 | 15~30 | 130 | 600~1100 | 204 | 1/2 | 40 | 0.5~1.2 |

| LC-45 | LC20 | 105 | 1071 | 90~120 | 20~40 | 140 | 600~1100 | 280 | 1/2 | 45 | 0.8~1.5 |

| LC-53 | LC30 | 166 | 1170 | 90~130 | 20~50 | 150 | 600~1100 | 406 | 1/2 | 53 | 1.5~3.5 |

| LC-60 | 227 | 1280 | 90~130 | 20~50 | 150 | 600~1100 | 722 | 1/2 | 60 | 4.5~6 | |

| LC-68 | LC40 | 289 | 1398 | 900~130 | 40~60 | 160 | 500~990 | 1016 | 1/2 | 68 | 4.5~6 |

| LC-75 | LC43 | 410 | 1677 | 120~150 | 50~90 | 180 | 450~980 | 1835 | 1/2 | 75 | 6~8.5 |

| LC-85 | 580 | 1777 | 130~160 | 60~100 | 190 | 360~690 | 2055 | 3/4 | 85 | 7~11 | |

| LC-100 | LC50 | 841 | 1997 | 150~180 | 80~110 | 200 | 350~700 | 3102 | 3/4 | 100 | 10~15 |

| LC-125 | 1337 | 2230 | 160~180 | 90~120 | 210 | 350~580 | 6190 | 1 | 125 | 14~18 | |

| LC-135 | LC20G | 1671 | 2287 | 160~180 | 100~150 | 210 | 350~500 | 6190 | 1 | 135 | 18~22 |

| LC-140 | LC81 | 1977 | 2307 | 160~220 | 120~180 | 210 | 350~450 | 6485 | 1 | 140 | 20~24 |

| LC-140F | LC81F | 2177 | 2307 | 160~220 | 120~180 | 210 | 350~750 | 6977 | 1 | 140 | 20~27 |

| LC-150 | LC30G | 2448 | 2607 | 170~190 | 130~190 | 230 | 280~400 | 9380 | 1 1/4 | 150 | 24~27 |

| LC-155 | LC121 | 2739 | 2700 | 180~230 | 180~240 | 250 | 200~300 | 10930 | 1 1/4 | 155 | 24~33 |

| LC-155F | LC121F | 2787 | 2700 | 180~230 | 180~240 | 250 | 200-400 | 11977 | 1 1/4 | 155 | 27~33 |

| LC-165 | LC131 | 3217 | 2977 | 200~240 | 190~260 | 260 | 150~300 | 13200 | 1 1/4 | 165 | 33~36 |

| LC-175 | LC151 | 3757 | 3220 | 210~240 | 200~250 | 270 | 120~200 | 15500 | 1 1/4 | 175 | 35~38 |

| LC-175L | LC151L | 4257 | 3350 | 210~240 | 200~250 | 290 | 120~200 | 16507 | 1 1/4 | 175 | 36~42 |

| LC-185 | 4307 | 3327 | 220~260 | 220~280 | 300 | 120~180 | 22380 | 1 1/4 | 185 | 37~50 | |

| LC-190 | 4986 | 3537 | 240~280 | 240~280 | 300 | 110~160 | 24280 | 1 1/4 | 190 | 40~50 | |

| LC-195 | 5400 | 3627 | 260~300 | 250~320 | 320 | 100~140 | 25490 | 1 1/4 | 195 | 45~55 | |

| LC-200 | 6388 | 3837 | 260~300 | 260~340 | 320 | 100~140 | 29700 | 1 1/4 | 200 | 48~60 | |

| LC-205 | 6780 | 3847 | 260~300 | 280~360 | 330 | 100~140 | 32260 | 1 1/4 | 205 | 52~60 | |

| LC-210 | 7017 | 3917 | 260~300 | 280~360 | 330 | 100~140 | 35670 | 1 1/₂ | 210 | 55~65 | |

| LC-220 | 7137 | 4047 | 260~300 | 280~360 | 330 | 100~140 | 37280 | 1 1/₂ | 220 | 60~65 | |

| LC-220L | 7520 | 4177 | 260~300 | 300~430 | 340 | 100~140 | 47000 | 1 1/₂ | 220 | 65~100 | |

| LC-230 | 8909 | 4227 | 260~300 | 330~430 | 340 | 90~130 | 49800 | 1 1/₂ | 220 | 70~100 | |

| LC-240 | 92200 | 4257 | 260~300 | 330~430 | 340 | 90~130 | 59800 | 1 1/₂ | 220 | 70~120 | |

| LC-260 | 10888 | 4877 | 260~300 | 420~550 | 350 | 90~130 | 62000 | 1 1/₂ | 220 | 90~150 | |

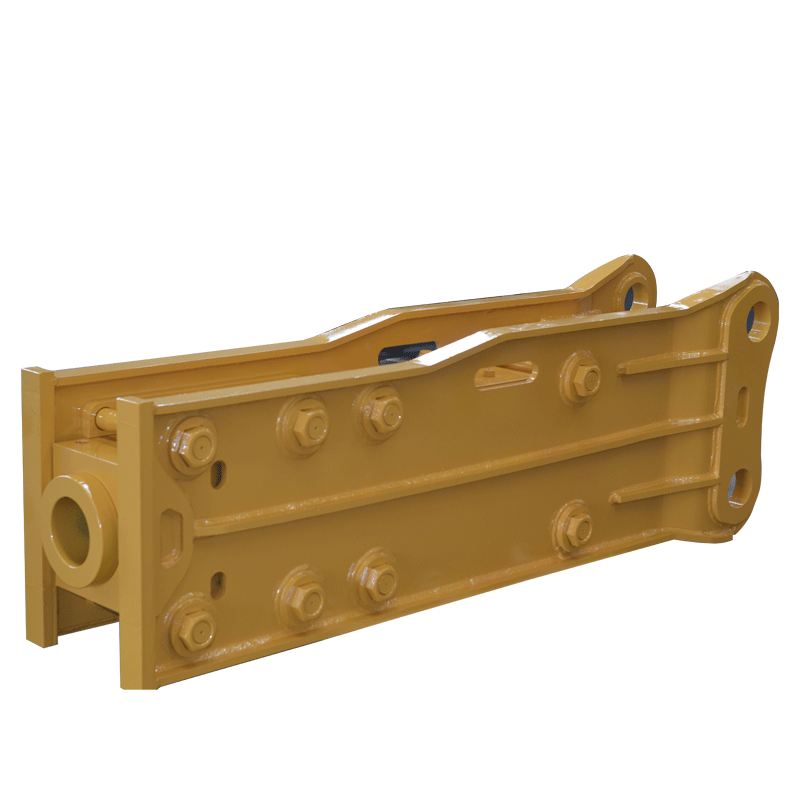

BREAKER advantages

The one piece breaker hammer offers several key advantages, including high efficiency, energy savings, environmental protection, and exceptional performance in underwater crushing operations.

When compared to traditional hydraulic piston breakers or conjoined straight hammer breakers—particularly high-frequency breakers—the cone piece breaker offers the following significant benefits:

High Efficiency and Energy Savings:

The high-frequency breaker stands out for its superior efficiency and energy-saving capabilities during operation. It is capable of conducting underwater crushing tasks without the need for modifications, which is essential in specialized construction environments.

Environmental Protection:

The high-frequency breaker reduces the risk of damage to the excavator’s hydraulic system, preventing issues caused by contaminants like black oil or metal debris. Additionally, it minimizes wear and tear on the excavator’s arms, significantly reducing environmental impact during operations.

Advantages in Underwater Crushing Operations:

The high-frequency breaker excels in underwater crushing tasks, particularly when dealing with materials like sandstone, weathered rock, limestone, and rocks found in Custer landform structures. Its performance in these conditions is far superior to that of traditional piston breakers.

BREAKER Application

Breaker hammers are widely utilized in various industries, including ore crushing, construction materials, metallurgical casting, and the chemical industry. As a crucial piece of mining equipment, they also find applications in civil engineering, concrete demolition, and other sectors.

In the mining industry, breaker hammers offer several key benefits, such as increased mineral acquisition rates, energy savings, and emission reductions. Their environmental friendliness, low maintenance costs, and user-friendly design make them highly efficient and versatile. As a result, they are extensively used across mining and related industries.

Contact With Us

If you have any questions please fell free to contact with us.