EU II emission standard and environmental protection engine supplies strong power. Modular design leads to reduce the amount of spare parts, low failure rate and conveniently maintenance.

Email: equip@lichmach.com

1.Powerful and high-efficiency engine

EU II emission standard and environmental protection engine supplies strong power.

Modular design leads to reduce the amount of spare parts, low failure rate and conveniently maintenance.

Inline type fuel pump produces higher injecting pressure, make the burning more fully.

Dual-class air filter ensure the inlet air high cleanness-degree. The filter element made of nanometer material has long cycle.

Strong cooling system ensure the engine running normally in hot summer.

Dual-class fuel filter with oil-water separator guarantee fuel high cleanness-degree, prolong engine life.

2.Flexible and reliable hydraulic system

Negative-flow full-power hydraulic control system makes responsibility more quickly.

The unique design spool of multi-way valve makes the operation more accurately.

High pressure cylinder is applied. And built-in buffer valve in it, which delay shock.

Return one-way flow control valve is adopted in hydraulic system make operation more softly.

Functions including boom priority, arm regeneration, settlement preventing, linear traveling, bucket convergent flow and etc. make.

3.High-load and efficient work device

Strengthened boom and arm are applied. Connecting parts are made of high stress low carbon cast steel.

Groove welding is applied for boom and arm, decreasing the welding stress, enhancing the welding strength, which be detected by supersonic device.

Oily resin gaskets are applied for clearance adjustment, which reduce the wear of substrate of structure and noise of operation.

Special high-density copper-based self-lubricating bearings are applied for key position, which reduce friction and resist to wear.

4.Safe and comfortable cab

Wide range of eyesight, high-power air conditioner, advanced control system, large-screen color monitor, adjustable suspension GRAMMER seat, six-point silicon oil shock absorber and etc. assisted human oriented design make operator comfortable, operation safe and reliable.

To comply with the national three-stage emission standard, a fully electronically controlled engine is used to accommodate various working conditions. A newly developed control system optimizes the power matching between pump and engine, resulting in low fuel consumption and high work efficiency.

A new type of hydraulic system is used in the crawler excavator. The optimized internal valve core ensures increased flow rate, reduced pressure loss, reasonable flow distribution, better movement coordination and easy operation.

The control system is newly developed to assure the full functionality of the entire excavator. It can intelligently adjust the hydraulic absorption power to accommodate the working conditions, and enable an optimized system matching.

The crawler excavator is equipped with a 5.7-inch glare-free color monitor featuring high-resolution and high-brightness, and an intelligent electronic monitoring system with functions of maintenance reminding, automatic fault diagnosis and alerting.

The new safe and reliable cab is utilized in the crawler excavator, it features an injection-molded interior and an automatic air conditioner for operator’s comfort.

The reliability of the entire excavator has been verified for 5000 hours during the development stage. All key components including structural parts, hydraulic parts, slewing bearings and engine have been tested under extreme working conditions.

4.Solid and stable traveling structure

| Specifications | |

| Operating weight | 22000kg |

| Standard bucket capacity | 1.1m³ |

| Arm length | 2910mm |

| Boom length | 5680mm |

| Engine | |

| Model | CUMMINS 6BTAA5.9-C150 |

| Type | Turbo-charged with inter-cooled |

| Power | 112KW/1950rpm |

| Max.torque | 614N•m at 1500rpm |

| No.of cylinders | 6 |

| Displacement | 5883cc |

| Hydraulic system | |

| Main pump: | |

| Type | Variable displacement axial piston pumps |

| Max.displacement | 2x112cc/rev |

| Working pressure | 35Mpa |

| Hydraulic motor: | |

| Swing | Fixed displacement axial piston motor |

| Travel | Variale displacement axial piton motors |

| Performance | |

| Swing speed | 13.9rpm |

| Max. travel speed H/L | 5.8/3.3km/h |

| Gradeability | 35° |

| Max. digging force of bucket | 137kN |

| Max.digging force of arm | 102kN |

| Ground pressure | 47kpa |

| Tank capacity | |

| Fuel tank capcity | 400L |

| Hydraulic tank capacity | 210L |

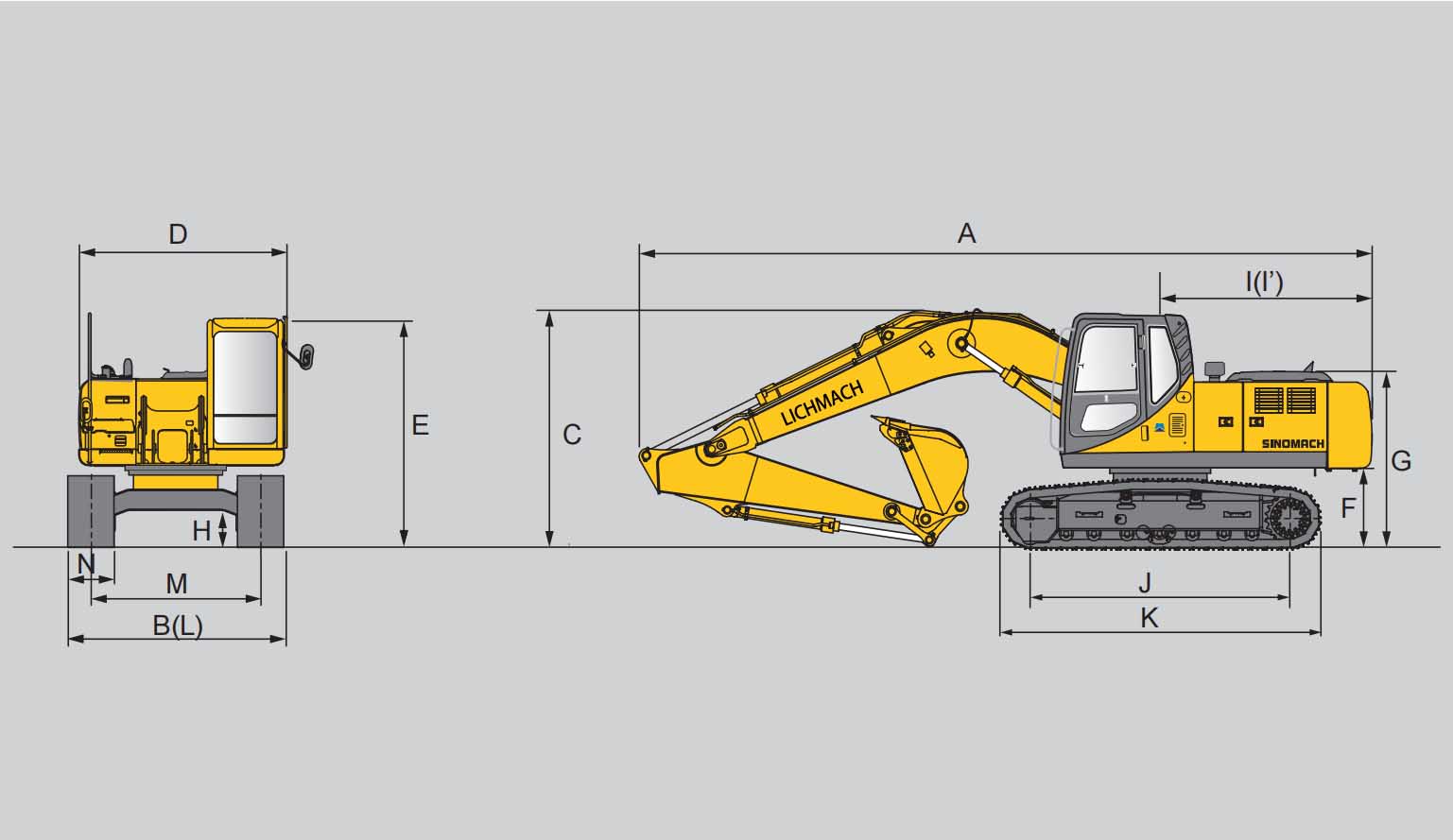

5.Dimensions(mm)

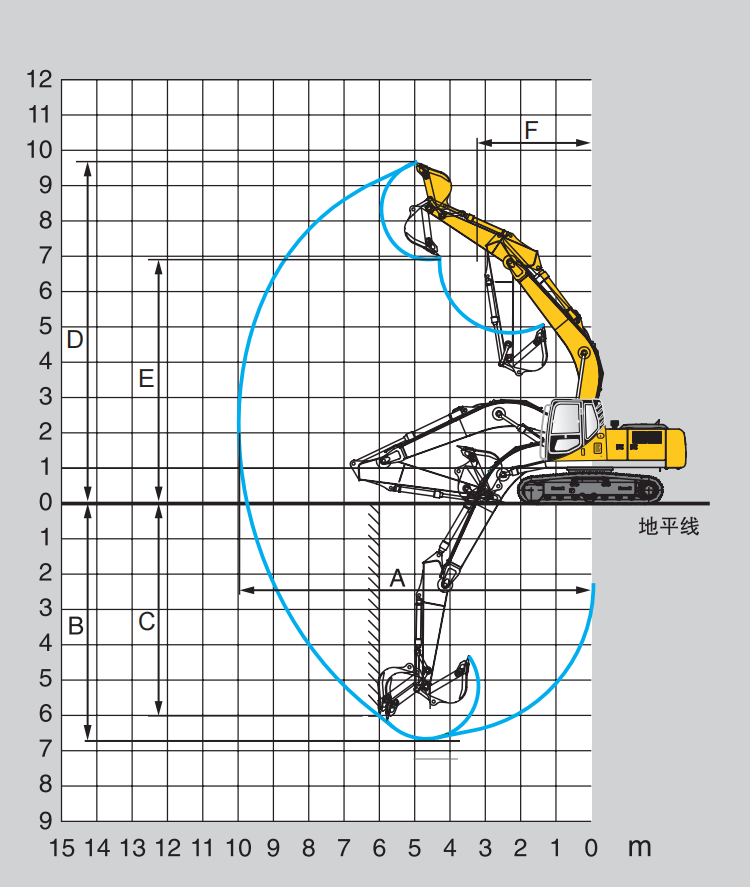

6.Working Range

| Item Unit(mm) | Item Unit(mm) | Item Unit(mm) |

| A Overall length 9520 | I Length of platform 2800 | A Max. digging reach 9970 |

| B Overall width 2990 | R Rear swing radius 2800 | B Max. digging depth 6707 |

| C Overall height of boom 3030 | J Track wheelbase distance 3650 | C Max. vertical wall digging depth 6107 |

| D Width of platform 2700 | K Chassis length 4440 | D Max. digging height 9665 |

| E Overall height of cab 2961 | L Chassis width 2990 | E Max.dumping height 6803 |

| F Ground clearance of counterweight 1028 | M Track gauge 2390 | F Min. swing radius 3560 |

| G Height of engine cover 2341 | N Standard width of track shoe 600 | |

| H Min.ground clearance 470 |

Contact With Us

If you have any questions please fell free to contact with us.