The GTY220 Bulldozer is equipped with advanced technology to enhance its performance, emissions, and overall reliability. The final drive employs a triangle spline, tip relief, and crowned gear drive configuration

Email: equip@lichmach.com

The GTY220 Bulldozer is engineered with cutting-edge technology to deliver superior performance, enhanced emissions control, and improved reliability. Its final drive system features a triangular spline, tip relief, and crowned gear drive design, ensuring better load balance, operational stability, lower noise levels, and extended transmission life.

Engine Power:

At the core of the GTY220 is the Cummins NT855-C280S10 engine — a robust, six-cylinder, four-stroke powerhouse that delivers a rated output of 175 kW at 1800 rpm. This ensures dependable performance for the most demanding construction and earthmoving tasks.

With a bore of 139.7 mm and stroke of 152.4 mm, the engine is optimized for high torque and consistent output. It uses a 24V, 11kW electric starter and is powered by a 24V battery system (12V × 2, 195Ah), ensuring reliable startups even in harsh working conditions.

Operating Weight

Weighing in at 23,500 kg, the GTY220 offers the mass and stability required for heavy-duty grading and material compaction. This operating weight improves ground penetration and ensures durable results across various terrain types.

Hydraulic System:

The advanced hydraulic system of the GTY220 operates at a working pressure of 14 MPa and delivers a rated flow of 262 L/min. It features a hand-operated plunger servo-controlled valve, allowing for precise and responsive control.

A hydraulic torque converter with a three-element, single-stage, single-phase design enables smooth stepless speed regulation, delivering optimized traction and fuel efficiency. This configuration enhances driving comfort, load handling, and overall transmission performance.

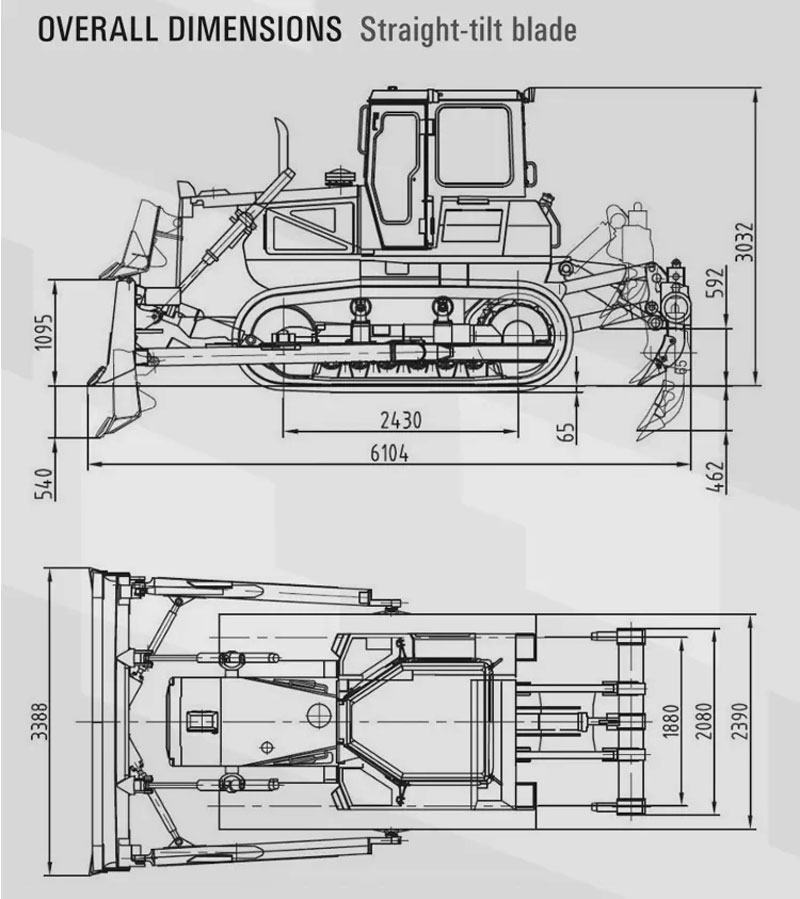

Blade Type

The GTY220 Bulldozer comes equipped with a variety of blade configurations to accommodate diverse job site requirements. Available blade types include:

Straight-Tilt Blade (S-Blade) – Ideal for fine grading and general-purpose earthmoving.

Angle Blade – Suited for side-casting and ditching operations.

Semi-U Blade – Designed for handling large volumes of material with a good balance of capacity and penetration.

These blades are engineered for maximum operational efficiency, with blade capacities ranging from 4.7 m³ to 7.5 m³, depending on the selected blade type. This flexibility allows operators to adapt to different ground conditions and material handling demands, enhancing productivity across various construction and mining applications.

Undercarriage and Transmission:

The GTY220 and GTY220S bulldozers feature a heavy-duty undercarriage engineered for durability and terrain adaptability. Key specifications include:

Track Pitch: 216 mm

Track Shoe Type: Sealed, single grouser

Track Width:

GTY220: 560 mm

GTY220S: 910 mm

Track Shoes per Side:

GTY220: 38

GTY220S: 45

Track Length on Ground:

GTY220: 2730 mm

GTY220S: 3480 mm

These features provide exceptional ground contact, traction, and stability across a variety of surfaces, ensuring optimal performance in demanding work environments such as soft soil, rocky terrain, or steep grades.

The transmission system employs a planetary gear setup with multi-disc hydraulic clutches, allowing for smooth and reliable gear shifts. The bulldozer offers:

3 Forward Speeds: 3.6 km/h, 6.5 km/h, 11.2 km/h

3 Reverse Speeds: 4.3 km/h, 7.7 km/h, 13.2 km/h

This allows operators to match ground speed to task demands, whether for fine grading, pushing, or heavy-duty dozing.

Designed with the operator in mind, the GTY220 features a spacious hexahedral cabin that provides:

Panoramic visibility for safer and more precise operation

Powerful ventilation and dust suppression, enhancing comfort during long working hours

Ergonomic controls for fatigue-free handling

For maximum durability and operator protection, the machine includes:

Hydraulic track tension adjustment for prolonged undercarriage life and reduced maintenance

ROPS (Roll-Over Protection Structure) and FOPS (Falling Object Protection Structure) systems, ensuring compliance with modern safety standards and safeguarding the operator in high-risk environments

Contact With Us

If you have any questions please fell free to contact with us.